Thin Films Series: The Invisible Layer in Everything You Touch, Use, and See

In this series, we’ve explored the mission-critical role of thin films in extreme environments: the thermal barrier coatings that allow jet turbines to operate at impossible temperatures, the nanoscale layers that form the architecture of every semiconductor chip, and the delicate electrode coatings that determine the performance of every battery. These are high-tech, specialized applications.

But the world of thin films is far broader and more intimate than that. They are a foundational, often invisible, technology that underpins nearly every aspect of modern life. From the car you drive, to the food you eat, to the water you drink, to the phone you’re likely reading this on—all are enabled by precisely engineered layers, often just a few microns or even nanometers thick.

This article, the fourth in our series, pulls back the curtain on the ubiquitous nature of thin films. We will explore the surprising and diverse applications of these coatings and functional films across everyday industrial, automotive, and consumer products, revealing a hidden world of material science that makes our world possible.

A map of just some of the everyday sectors where thin film technology is indispensable.

Your Car: A Multi-Layer Coating Masterpiece

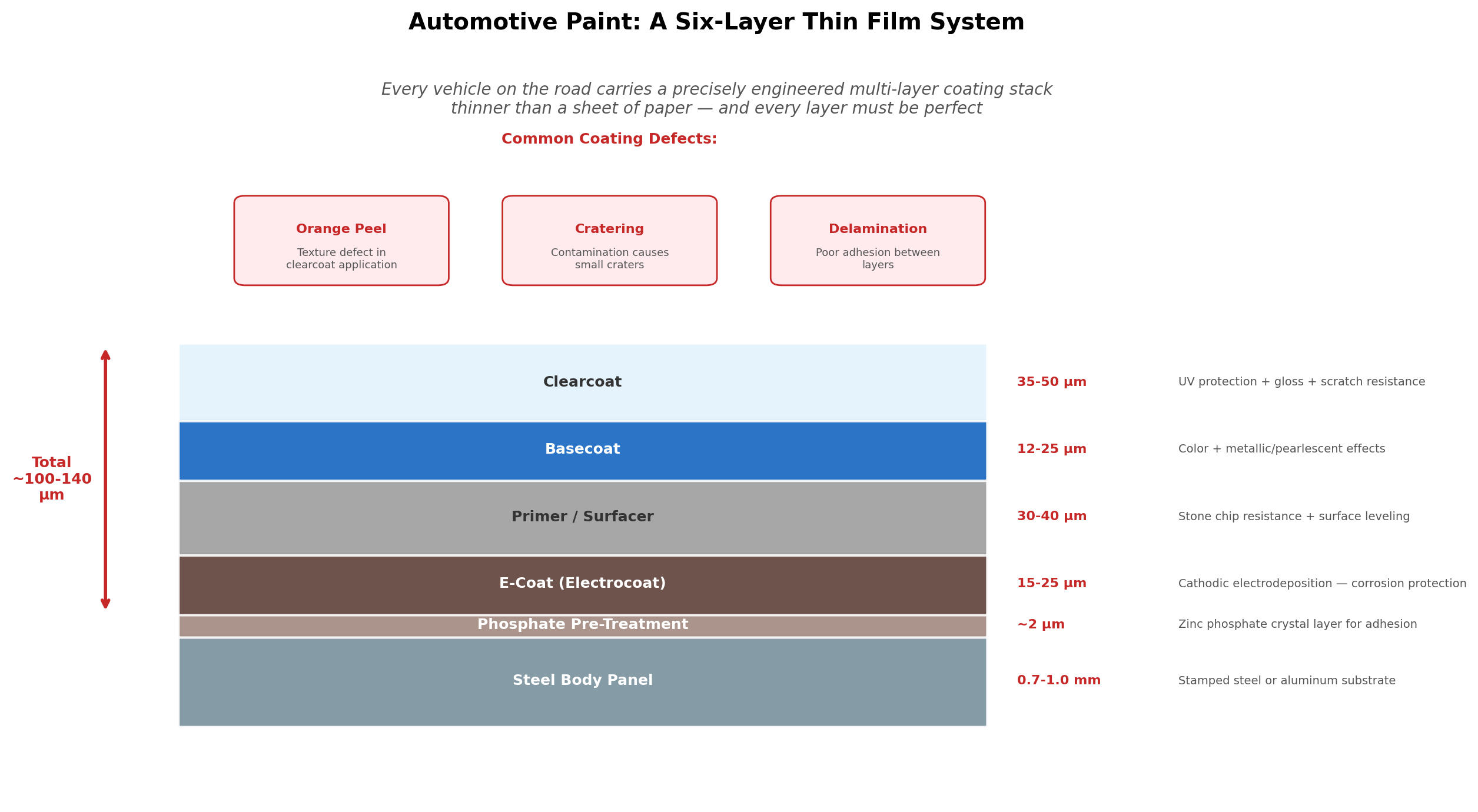

Every vehicle that leaves an assembly line is a rolling testament to the power of thin film technology. The flawless, glossy finish on a new car is not a single layer of paint, but a complex, multi-layer system, with each layer performing a distinct function. The total stack is typically only 100-140 micrometers thick—about the width of a human hair—but it represents a marvel of material science and process engineering.

The typical automotive paint system is a stack of six distinct layers, each with a specific role in protecting the vehicle and providing a perfect finish.

The process involves applying four primary coating layers over the pre-treated metal body:

- E-Coat (Electrocoat): A 15-25 µm layer applied via cathodic electrodeposition. This is the foundation of the car’s corrosion protection.

- Primer/Surfacer: A 30-40 µm layer that provides adhesion for the subsequent layers, levels out minor surface imperfections, and adds crucial resistance to stone chips.

- Basecoat: The layer that provides the color and visual effects (like metallic or pearlescent finishes). It is typically only 12-25 µm thick.

- Clearcoat: The final 35-50 µm layer that provides gloss, scratch resistance, and protection from UV radiation and environmental contaminants.

Achieving a perfect finish across millions of vehicles is a monumental manufacturing challenge. The global automotive OEM coatings market is valued at over $20 billion, and any defect in these thin layers can lead to costly rework and warranty claims [1]. Beyond the paint, thin films are also used for wear-resistant coatings on engine parts, thermal barriers on exhaust components, and anti-reflective coatings on dashboard displays.

Your Food: Kept Fresh by Nanoscale Barriers

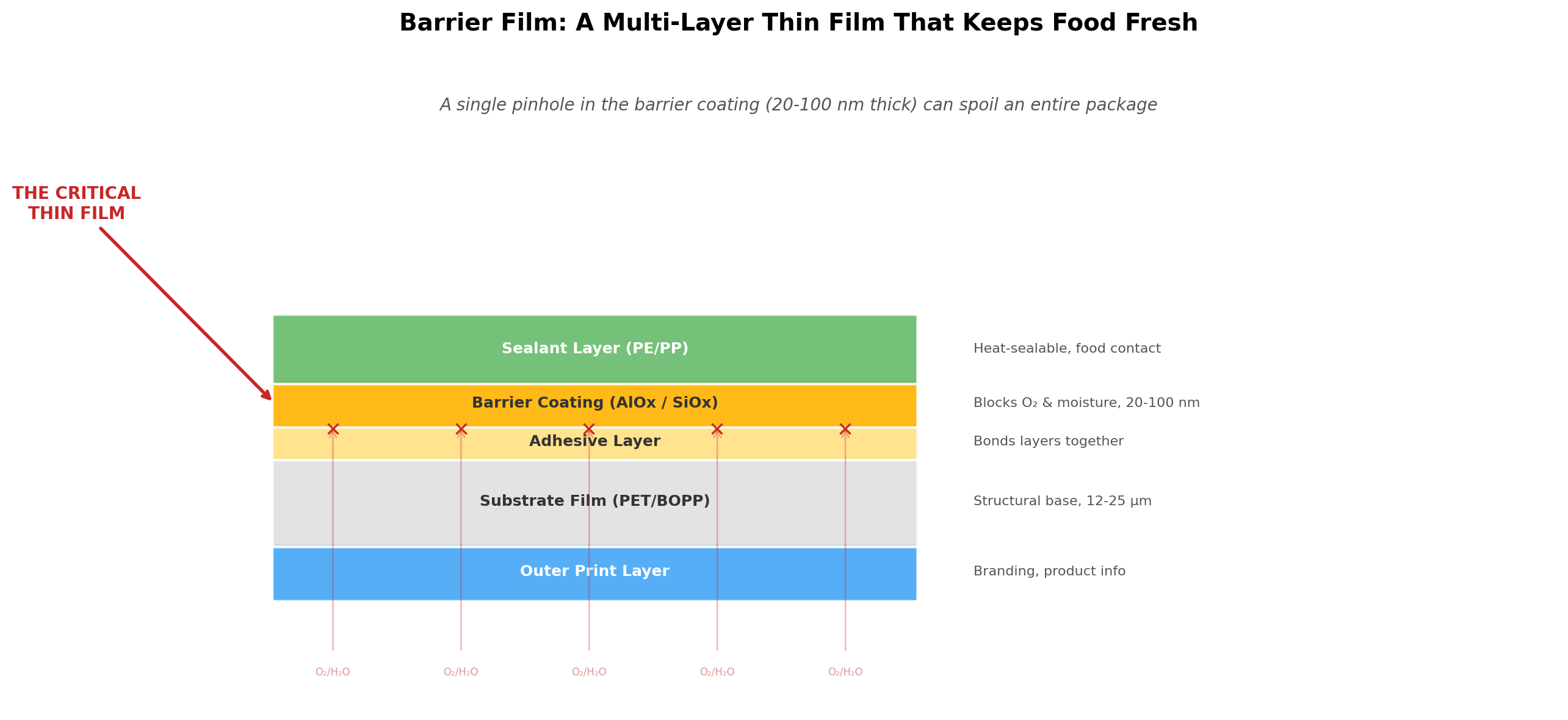

The plastic bag holding your salad or the pouch for your coffee is far more complex than it appears. Modern food packaging relies on barrier films to protect its contents from oxygen and moisture, the two primary enemies of freshness and shelf life. The technology that provides this protection is an incredibly thin, transparent coating, often just 20-100 nanometers thick.

These barrier films are typically multi-layer structures produced in high-volume, roll-to-roll processes. A substrate film (like PET) is coated with an ultra-thin layer of a barrier material, such as aluminum oxide (AlOx) or silicon oxide (SiOx). This invisible ceramic layer is what prevents gases from passing through.

A single pinhole or defect in the nanometer-scale barrier layer can compromise the entire package, leading to food spoilage and waste.

The market for these films is enormous, projected to exceed $35 billion by 2030 [2]. The manufacturing challenge is immense: a single, microscopic pinhole in the barrier layer across miles of film can render the packaging useless. This makes in-line quality control essential to ensure the integrity of the barrier and the safety of the food supply.

Your World: Protected by a Thin Film Shield

Beyond specific products, thin films are a critical tool for protecting our infrastructure and enabling a more sustainable future. The applications are nearly limitless.

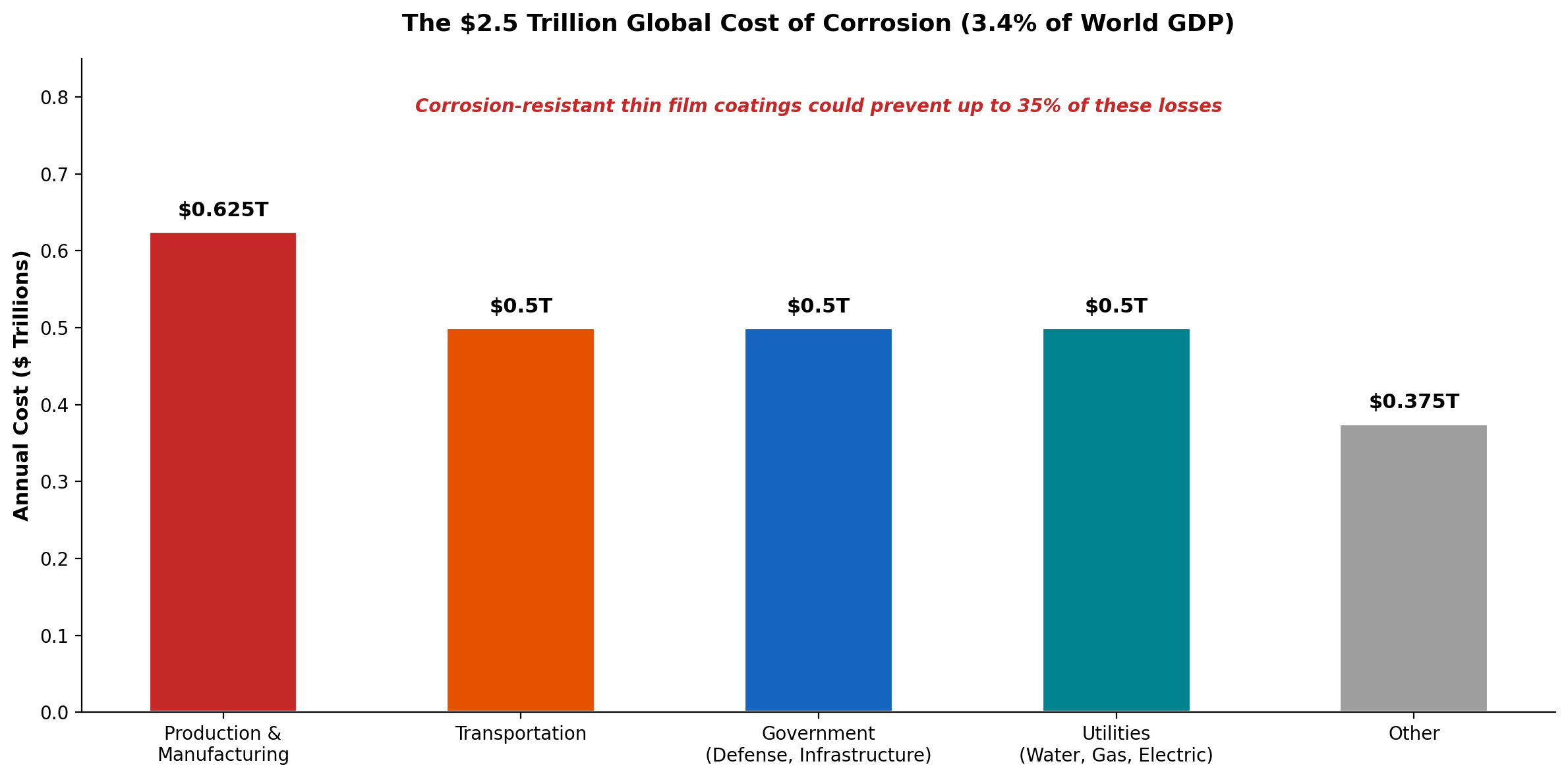

The $2.5 Trillion Problem of Corrosion

Rust is not just an eyesore; it is a relentless force of decay that costs the global economy an estimated $2.5 trillion every year, equivalent to 3.4% of global GDP [3]. Corrosion-resistant coatings are the primary defense against this staggering loss. These thin films protect everything from bridges and pipelines to ships and industrial machinery, extending their lifespan and ensuring public safety.

Source: NACE International [3]

Enabling Clean Water and Energy

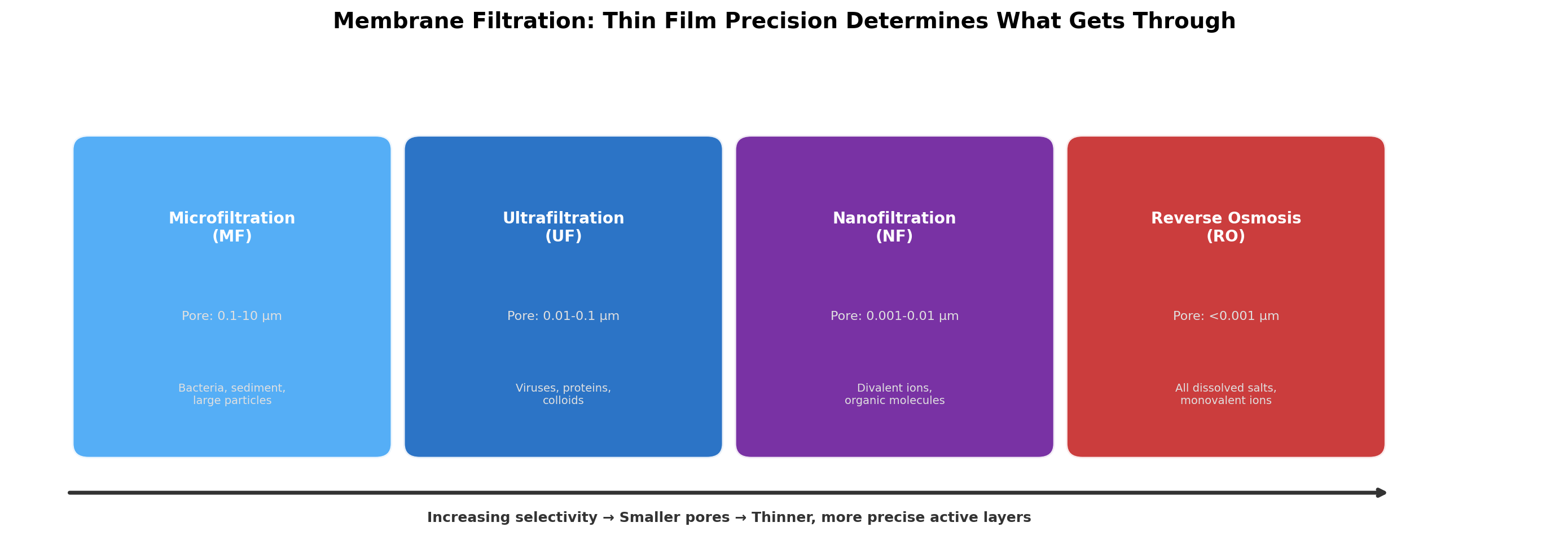

Membrane separation is a technology at the heart of water purification, desalination, and the emerging hydrogen economy. The performance of these systems depends entirely on the quality of the membrane—a thin film with precisely controlled pores.

- Reverse Osmosis (RO): Membranes with pores less than 0.001 µm are used to turn seawater into fresh drinking water.

- Gas Separation: Specialized polymer membranes are used to capture CO2 or purify hydrogen for fuel cells.

As the world grapples with water scarcity and the energy transition, the market for these high-performance membranes is projected to grow to over $27 billion [4].

From filtering bacteria to separating individual salt ions, the performance of a membrane is determined by the precision of its thin film active layer.

The Unseen Layers of Modern Life

The list of applications goes on, touching nearly every high-tech and industrial sector:

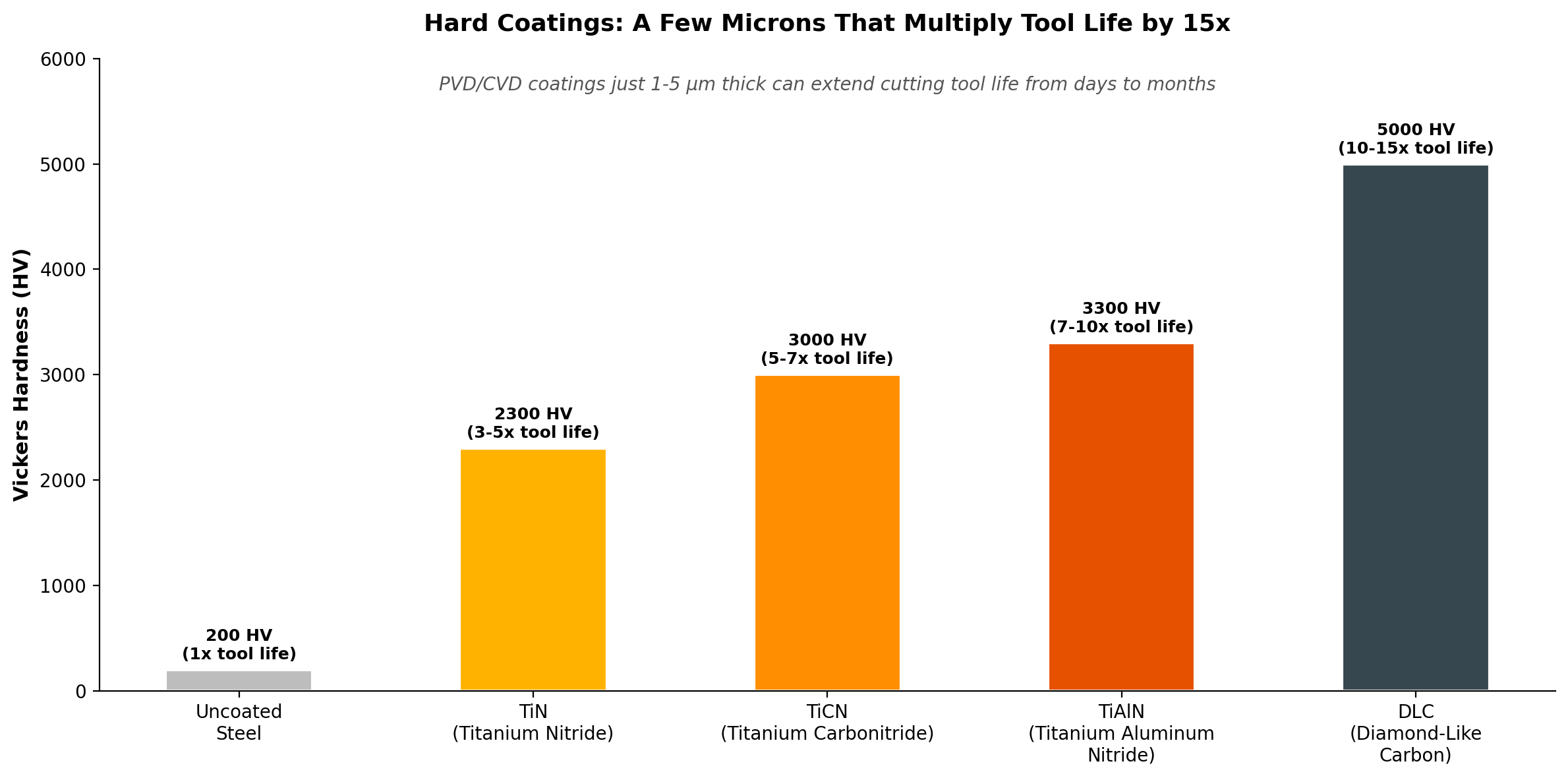

- Hard Coatings: A few microns of titanium nitride or diamond-like carbon on a cutting tool can increase its lifespan by more than 10 times.

- Medical Devices: Biocompatible coatings on implants, stents, and surgical tools are essential for patient safety.

- Display Films: The vibrant screen on your phone or TV uses a complex stack of a dozen or more optical films to manage light and color.

From the mundane to the mission-critical, thin films are the invisible enablers of the modern world. While they often go unnoticed, the precision and quality of these microscopic layers have a macroscopic impact on the performance, durability, and safety of the products we rely on every day.

References

[1] Grand View Research. (2024). Automotive OEM Coatings Market Size, Share & Trends Analysis Report. https://www.grandviewresearch.com/industry-analysis/automotive-oem-coatings-market

[2] Grand View Research. (2024). Barrier Films Market Size, Share & Trends Analysis Report. https://www.grandviewresearch.com/industry-analysis/barrier-films-market

[3] NACE International. (2016). International Measures of Prevention, Application, and Economics of Corrosion Technologies Study. http://impact.nace.org/economic-impact.aspx

[4] Grand View Research. (2023). Membrane Separation Market Size And Share Report, 2030. https://www.grandviewresearch.com/industry-analysis/membrane-separation-market

Written by Bogdan Cristei and Manus AI